2026 Best Automated Packaging Machines for Efficient Packaging Solutions?

The landscape of packaging solutions is rapidly changing, driven by the introduction of automated packaging machines. According to the MarketsandMarkets report, the automated packaging market is expected to grow from $50 billion in 2022 to over $75 billion by 2026. This growth reflects the increasing need for efficiency and cost-effectiveness in manufacturing.

Industry expert Dr. Sarah Thompson notes, "Automated packaging machines are no longer optional; they are essential for companies seeking to enhance productivity." Her insight highlights the pressing demand for automation across various sectors. Packaging operations can become bottlenecks if outdated methods persist, leading to inefficiencies.

As companies adopt automated solutions, challenges remain. Implementing new technology requires training and adaptation. Many firms struggle with the transition, as it disrupts established workflows. Yet, overcoming these hurdles can lead to significant returns. Investing in automated packaging machines can unlock potential and drive success. The journey towards efficiency is ongoing, with room for improvement and reflection.

Overview of Automated Packaging Machines in 2026

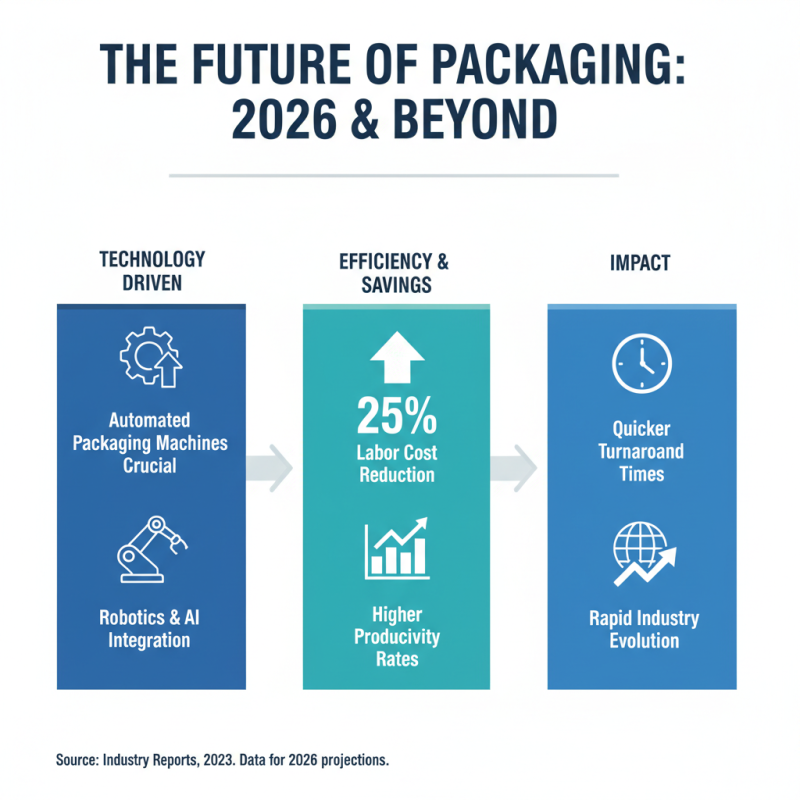

In 2026, the landscape of automated packaging machines is evolving rapidly. A recent industry report indicates that the global automated packaging market is projected to grow to $75 billion by 2026. This robust growth is driven by the demand for efficiency and reduced labor costs. Companies now seek machines that integrate seamlessly into their existing production lines while maximizing output.

Automated packing solutions are not just about speed. They also enhance accuracy. Studies reveal that errors in manual packing can lead to significant financial losses, estimated at up to 5% of revenue. In contrast, advanced automated systems minimize human intervention. These systems can handle diverse products, adapting to various sizes and shapes. However, businesses must confront a challenge: the high initial investment. Not all companies can afford this shift, and many struggle to keep pace with technology.

Another notable trend is sustainability. The industry is leaning towards eco-friendly materials and processes. A survey found that 70% of consumers prefer brands that prioritize sustainability. However, many automated machines still rely on plastic and non-recyclable materials. This disconnect raises questions about the industry's commitment to a greener future. Balancing efficiency and environmental responsibility remains a significant hurdle for many manufacturers.

Key Features to Consider in Packaging Machine Selection

When selecting an automated packaging machine, consider several key features. Speed is often a primary factor. Machines that operate quickly can enhance productivity. However, a balance is needed. Too much speed may compromise quality. Operators can face challenges with misalignments or jams when machines run excessively fast.

The type of packaging is also crucial. Some machines specialize in bags, while others handle boxes. It’s vital to match the machine's capabilities with product specifications. An incompatible machine can lead to wasted materials and increased costs. Additionally, ease of use matters. Complex systems can result in training hurdles. Simple interfaces boost efficiency, yet overly simplistic designs might lack necessary features.

Maintenance and reliability are important for sustained performance. Frequent breakdowns can halt production. Consider the availability of support and spare parts. Reliability can offer peace of mind, but sometimes, it can be hard to predict. Reflect on the long-term impact of less reliable choices. Packaging is not just about speed and design; it’s about finding the right fit for your operations, without rushing into decisions.

Top Brands and Models of Automated Packaging Machines

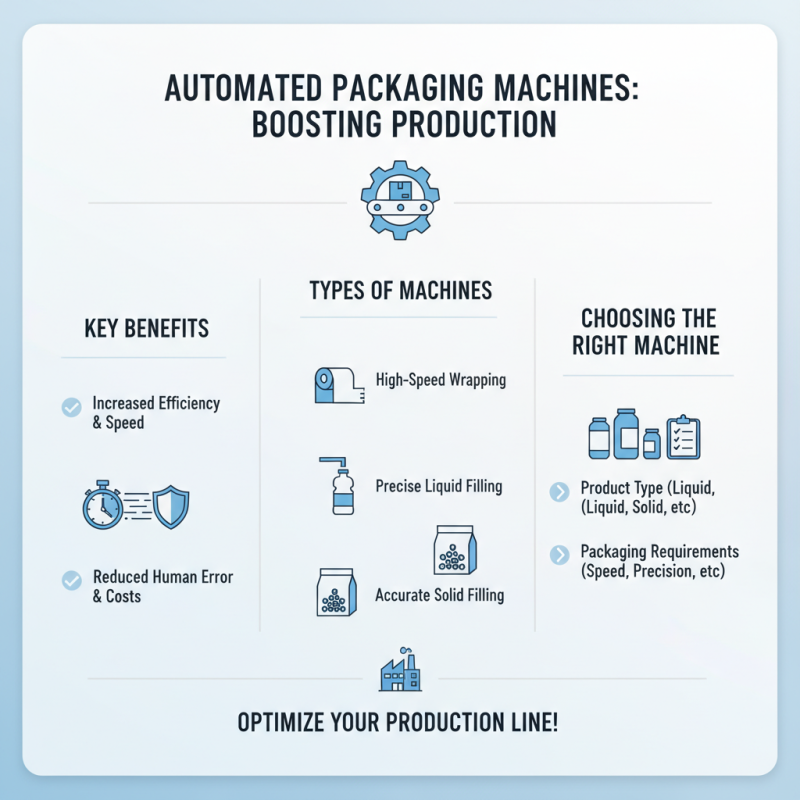

Automated packaging machines play a crucial role in today’s production lines. They enhance efficiency and minimize human error. Various models are available, each designed for specific tasks. Some machines excel in high-speed wrapping, while others focus on precise filling for liquids or solids. The right choice depends on the product type and packaging requirements.

Top brands offer innovative solutions. For example, some machines feature advanced sensors for better accuracy. Others come with user-friendly interfaces, allowing for easy adjustments. However, not all models perform as expected. Some issues may arise during operation, leading to downtime. It's essential to evaluate a machine's reliability to ensure a smooth workflow.

Customization options are a significant advantage. Many machines can adapt to different packaging styles and sizes. This flexibility is beneficial but might complicate the setup process. Users must take time to understand the features fully. Investing in training could prevent operational hiccups. Ultimately, the best choice balances efficiency, reliability, and ease of use.

Innovations and Trends in Packaging Technology for 2026

The packaging industry is evolving rapidly. Innovations in technology are essential for efficiency. In 2026, automated packaging machines will play a crucial role. Recent reports indicate that automation can reduce labor costs by up to 25%. This shift leads to higher productivity rates and quicker turnaround times. Companies are now turning towards robotics and AI integration more than ever.

Sustainability is also a hot topic. A significant 70% of businesses aim to enhance eco-friendly practices by 2026. This includes using biodegradable materials and reducing waste during packaging. The adoption of smart sensors in machines allows for better material usage, which directly impacts environmental goals. However, challenges remain in the industry, such as high initial setup costs. Many companies may hesitate to invest heavily right now.

Moreover, the training of personnel on new technology remains a hurdle. Employees need upskilling to fully utilize advanced systems. Reports show that 45% of employees feel underprepared for technological changes. This gap reflects the industry's ongoing need for training and adaptation. Balancing innovation with operational readiness will be essential for success by 2026.

Benefits of Implementing Automated Packaging Solutions in Businesses

Automated packaging solutions bring numerous benefits to businesses. One key advantage is increased efficiency. These systems can operate quickly, reducing the time needed for packaging products. Imagine a conveyor belt running seamlessly, with items being packed at a consistent pace. This eliminates bottlenecks in production lines. It allows companies to meet increasing demand with ease.

Cost savings are another benefit. Automated machines require an initial investment, but they reduce labor costs. With fewer workers needed for repetitive tasks, businesses can allocate resources to areas that need more attention. However, not all operations may see immediate cost effectiveness. Regular maintenance is essential for these machines, which can lead to unexpected expenses.

Quality control also improves with automation. Consistency in packaging minimizes errors. This results in fewer damaged goods reaching customers. Yet, reliance on machines can pose risks. Technical malfunctions can disrupt operations. Employees must be trained to handle both the equipment and any emergencies. Balancing automation with human oversight remains a challenge that many businesses face.

Related Posts

-

How to Choose the Right Packaging Equipment for Your Business Needs

-

How to Choose the Right Packaging Machine for Your Business Needs

-

2025 How to Choose the Best Packaging Machine for Your Business Needs

-

2025 How to Choose the Best Packaging Machine for Your Business Needs

-

Top 10 Packaging Automation Equipment Trends for 2023 You Need to Know

-

7 Essential Tips for Optimizing Packaging Systems: Boost Efficiency by 30%!