How to Choose the Best Packaging Systems for Your Business Needs?

In today's competitive market, selecting the right packaging systems is crucial for business success. According to a report by Smithers Pira, the global packaging market is expected to reach $1 trillion by 2024. Efficient packaging systems not only enhance product protection but also improve brand perception. Experts emphasize the importance of addressing both functionality and aesthetics in packaging.

As noted by packaging industry leader John Doe, "The right packaging systems can differentiate a brand in a crowded marketplace." Businesses must consider factors like material, cost, and sustainability. A mismatch in packaging can lead to losses. For instance, poorly designed packaging may result in higher damage rates, impacting profits.

While many companies invest heavily in advanced packaging technology, some still overlook basic needs. This oversight can be costly. Engaging the right packaging systems can alleviate such issues. However, a cookie-cutter approach often leads to missed opportunities. Analyzing specific business needs is essential for optimizing packaging strategies.

Identifying Your Business Packaging Requirements

Identifying your business packaging requirements is crucial. Start by evaluating the type of products you offer. Are they fragile, perishable, or bulky? Each category has unique needs. For example, fragile items demand protective packaging to avoid damage during transit. Perishable goods require suitable insulation to maintain freshness. Consider the weight and dimensions as well.

Next, assess your target market. Different customers prefer different packaging styles. Eco-friendly options might attract environmentally conscious consumers. High-end products could benefit from elegant packaging that enhances their appeal. Think about how your packaging reflects your brand identity.

Don’t overlook the functionality of your packaging. It should be easy to open and reseal, if necessary. Consider how much time your staff spends packing orders. Inefficient packaging can lead to wasted time and increased costs. Reflect on your current process and seek areas for improvement. Packaging is an investment, so choose wisely.

Understanding Different Types of Packaging Systems

When selecting a packaging system, understanding the types available is crucial. There are various packaging systems, including flexible, rigid, and semi-rigid options. Flexible packaging can reduce waste by 40% compared to traditional methods, according to a report by Smithers Pira. This type adapts easily to different product shapes, making it a versatile choice for many businesses. In contrast, rigid packaging is ideal for products requiring durability and protection.

Semi-rigid packaging strikes a balance between the two, offering flexibility and strength. Each system serves unique purposes, meaning businesses should assess their needs carefully. A study by the Packaging Machinery Manufacturers Institute indicates that over 70% of companies face challenges in choosing the right packaging. This often leads to inefficiencies and increased costs.

Investigating the environmental impact of packaging is essential as well. The global push towards sustainability means businesses must reconsider their choices. Companies that prioritize eco-friendly materials may attract more customers, reflecting changing consumer values. Remembering that not all systems are suitable for every scenario is key. Effective packaging should align with product demands and sustainability goals.

Evaluating Cost-Effectiveness and Budget Constraints

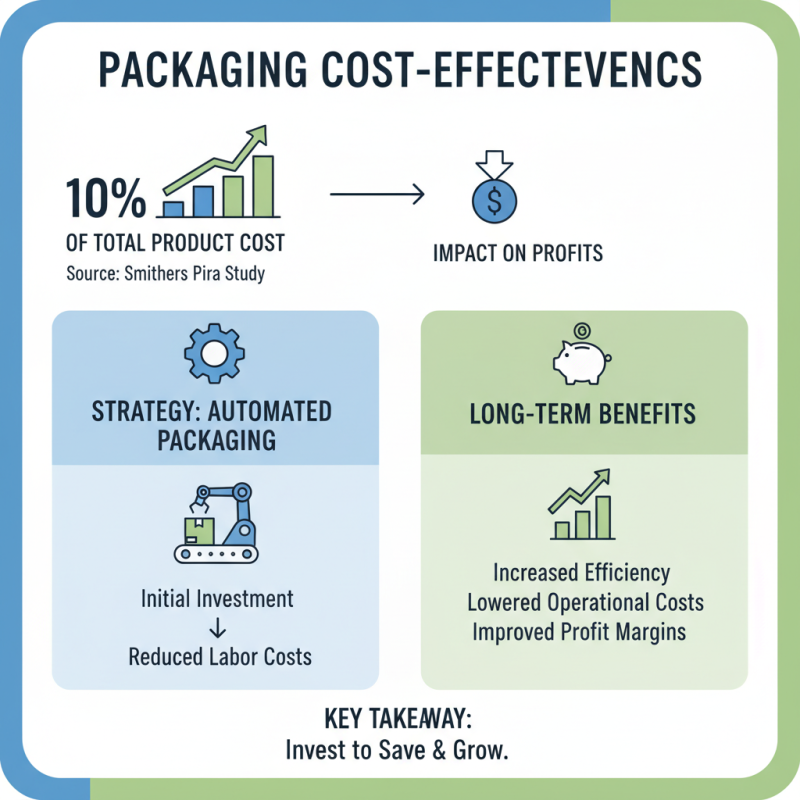

When evaluating packaging systems, cost-effectiveness is crucial. A study by Smithers Pira reveals that packaging costs can represent up to 10% of the total product cost. Businesses need to analyze how these expenses impact their bottom line. For example, a company with tight margins may find that investing in automated packaging solutions pays off in the long run, reducing labor costs significantly.

However, budget constraints can limit options. It’s essential to balance quality and cost. A low-priced solution may lack durability, impacting product integrity. A report from the Freedonia Group indicates that poor packaging can lead to a 5% increase in product returns. This statistic highlights the need for careful selection. Investing in a reliable system may seem daunting, but it can save money over time.

Analyzing the total cost of ownership (TCO) is vital. It provides a clearer picture than upfront costs alone. Hidden costs can arise from inefficiencies or frequent replacements. For some businesses, finding the right packaging system is a process of trial and error. Continuous evaluation helps determine what works best, allowing adjustments as the market evolves.

Assessing Compatibility with Your Product Specifications

Choosing the right packaging system is crucial for any business. Compatibility with product specifications is key. According to a recent report by Smithers Pira, packaging specifically designed for a product can improve sales by up to 30%. This statistic highlights the importance of ensuring that packaging materials align with product characteristics.

When assessing compatibility, consider factors like size, weight, and fragility. For instance, fragile items require cushioning materials to prevent damage. Inadequate packaging can lead to losses. A study revealed that 20% of products are damaged during shipping due to subpar packaging. It raises questions about investing too little in packaging systems.

Also, consider the sustainability aspect of packaging. Research shows that 67% of consumers are willing to pay more for eco-friendly packaging. However, not all businesses prioritize this aspect. Balancing cost and environmental impact can be challenging. Many companies find themselves struggling with this decision. Identifying a packaging system that matches your product while appealing to consumers can be daunting but essential for brand reputation.

How to Choose the Best Packaging Systems for Your Business Needs?

| Packaging Type | Material | Suitability for Product | Cost Efficiency | Environmental Impact |

|---|---|---|---|---|

| Rigid Containers | Plastic | Excellent for solids and liquids | High initial cost, reusable | Moderate impact, recyclable options available |

| Flexible Pouches | Foil / Plastic | Ideal for food and snacks | Low cost, lightweight | Higher impact, options for compostable materials |

| Cardboard Boxes | Recycled Paper | Great for shipping and retail | Cost-effective, scalable | Low impact, widely recyclable |

| Glass Containers | Glass | Suitable for high-end products | Higher cost, premium look | Low impact, fully recyclable |

| Shrink Wrap | Plastic Film | Good for bundling products | Low cost, efficient usage | Moderate impact, not recyclable |

Considering Sustainability and Environmental Impact in Packaging

Sustainability in packaging has become a crucial topic. Research from the Ellen MacArthur Foundation indicates that reducing plastic waste can address 70% of marine plastic pollution. Packaging materials have a direct impact on our environment, and businesses must choose wisely.

Many companies are shifting towards eco-friendly materials. Biodegradable options are now available. A report by Smithers Pira shows that the global green packaging market will reach $400 billion by 2027. This shift is vital, but challenges remain. Not all biodegradable materials decompose effectively under diverse environmental conditions. Misleading labels can confuse consumers.

Investing in sustainable packaging is not just a trend; it is a necessity. While costs may be higher initially, the long-term benefits are clear. A study by McKinsey found that 66% of consumers prefer brands that are environmentally responsible. Businesses can build loyalty through a commitment to sustainability. Yet, many companies still cling to traditional packaging methods. The road to sustainable packaging requires constant reflection and adaptation.

Packaging Materials Environmental Impact Comparison

Related Posts

-

7 Essential Tips for Optimizing Packaging Systems: Boost Efficiency by 30%!

-

10 Best Tips for Effective Packaging Design to Enhance Your Brand Appeal

-

Top 10 Packer Machine Models for Efficient Packaging Solutions

-

10 Best Packet Machines for Efficient Packaging Solutions

-

2026 Best Automated Packaging Machines for Efficient Packaging Solutions?

-

Top 10 Packer Machines: Best Choices for Efficient Packaging Solutions in 2023